The Best Strategy To Use For Sandblasting Adelaide

Wiki Article

The Best Guide To Sandblasting Adelaide

Table of ContentsSee This Report on Sandblasting AdelaideThe smart Trick of Sandblasting Adelaide That Nobody is Talking AboutSandblasting Adelaide Things To Know Before You Get ThisSandblasting Adelaide Things To Know Before You Buy

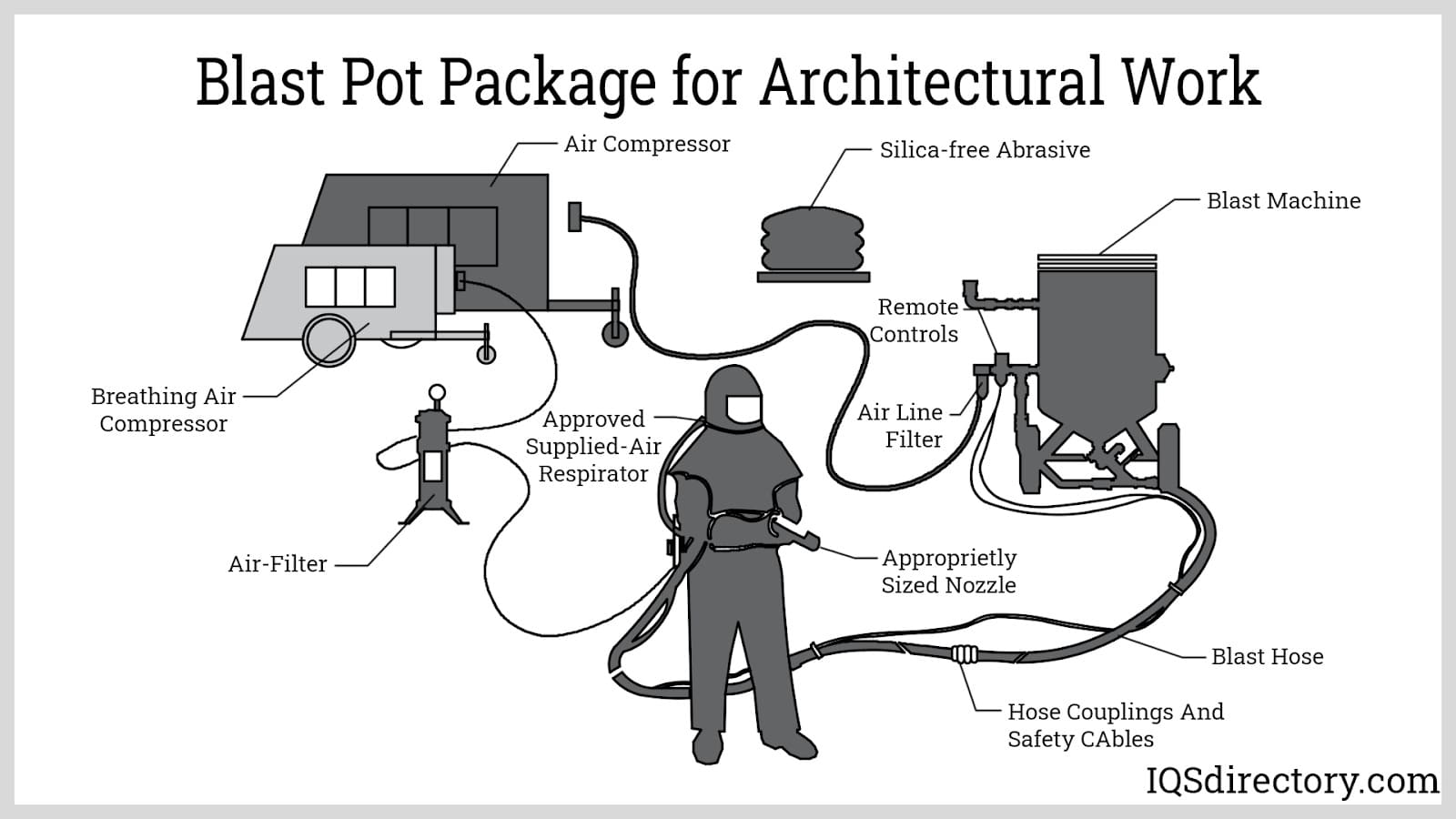

When making use of a blast nozzle, it is very important to make certain that the tip rotates at broadband. This permits the product to be displaced of the equipment's pipe as well as onto surfaces. There are various types of nozzles offered such as: - Straight (for rough or hefty blasting) - Conical (for smooth, boring or final blasting) - Diamond (for high efficiency as well as efficiency) - Fluted (for low pressure as well as mild cleansing of soft materials like wood and also fabric) - Strengthened flutes (for hefty obligation applications such as eliminating paint from concrete walls).When it comes to options, there are a number of methods you can go around sandblasting. There is a whole lot of variety when it comes to equipment you can select from.

The procedure of removing paint, rust, or various other surface area contaminants from metal surface areas is called blowing up. In blowing up, suction is created by pressed air or a fluid agent to draw paint, corrosion, lead, or various other pollutants off the surface as well as into the air.

Media blasting is generally made use of to get rid of paint, corrosion, and also various other pollutants from ferrous metal surfaces while soft drink blasting is made use of to get rid of paint, rust, and various other pollutants from non-ferrous steels. Both techniques are utilized to eliminate paint and corrosion. Nonetheless, soda blowing up jobs quicker than media blowing up since soft drink can reduce via the paint and also rust whereas media blowing up has to operate at it longer to make it through the paint and also onto the bare steel.

Unknown Facts About Sandblasting Adelaide

Sandblasting jobs well on surfaces that are constructed out of concrete. No bit installs itself into the surface. Sandblasting uses sand bits under high pressure with oxygen to eliminate pollutants from steel surface areas such as steel, iron, light weight aluminum, brass, tungsten carbide, titanium, and also graphite. Media blowing up is the most common way to remove surface impurities from steel.

For instance, media blasting can be made use of on airplane components that must-have stainless steel rust removed. It has also been made use of in high-pressure air scrubbers for fuel systems and engine components. Media blowing up is likewise used for getting rid of lead from warm rods along with finishings on potable water pipes.

Media blowing up is utilized to eliminate paint, rust, and impurities from non-ferrous steels such as brass and also light weight aluminum. Soft drink blasting is the very best technique for removing surface area contamination on ferrous metals since it makes use of a high-pressure stream of pressurized soda solution that consists of a mixture of salt bicarbonate and water.

This creates a high-velocity, high-pressure decrease which forces the liquid to exit the nozzle. Media blowing up is one of the most typical way to get rid of click for info surface area impurities from steel. Media blasting is frequently utilized in high-pressure air scrubbers for fuel systems and also engine components. It has actually additionally been made use of in high-pressure air scrubbers for gas systems and also engine components.

The Greatest Guide To Sandblasting Adelaide

Soda blowing up can be done with belts, buckets, and various other nozzles. The nozzle is connected to completion of a stick that holds the soda solution as well as rates it up when it comes out of the nozzle. Other systems use stress to guide the soda solution towards a target surface area at broadband.

Complying with sandblasting, the surface area may be too harsh to utilize instantly. Media blowing up takes longer than soda blasting to do the task since anything that is blown up off has to be collected and disposed of effectively.

The smart Trick of Sandblasting Adelaide That Nobody is Discussing

Rough sandblasting can be used on almost any kind of hefty product surface area of business as well as industrial ranch devices; my company as an example, for tractor view it cleansing and also restoration. Naturally, this is reliant on the correct mix as well as ratio of media, atmospheric pressure, volume and blast nozzle. This is why it is very important to pick the ideal heavy devices blasters in Melbourne who are not just certified yet possess the specialist knowledge and also expertise to bring out a successful blasting activity plan which expands the longevity of your business as well as commercial tools and also elements.

This is due to its distinct feature of supplying atmospheric pressure and also quantity which relocate the sandblasting media with the hose as well as blast nozzle at high speed to eliminate unwanted layers for heavy equipment restoration. Blast nozzle, Various blast nozzles are made use of for different surface areas which call for hefty tools cleansing.

The abrasive is what does all the heavy equipment cleaning and surface preparation job. Sandblasting Adelaide. There are several factors that influence the performance of the abrasive made use of. These consist of the high quality of the rough to deal with crud, corrosion or any kind of undesirable surfaces; the make-up of the surface area; the kind of rough; reuse prospective to preserve environmental health and wellness; and also the quality of the cleansing.

Report this wiki page